| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Mingrui

Model Number : MR-IN-0573

Certification : ISO9001

Place of Origin : China

MOQ : 100 pieces

Price : negotiable

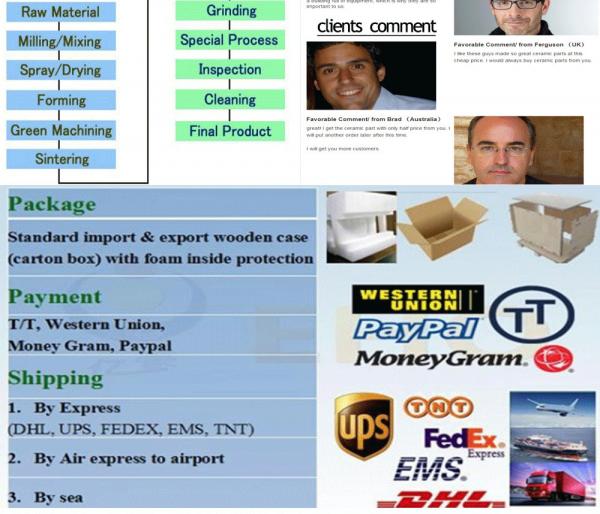

Payment Terms : L/C, T/T, Western Union, MoneyGram, D/P, D/A

Supply Ability : 8000 pieces month

Delivery Time : 23 working days after the order confirmed

Packaging Details : intertional carton box

Material : Zirconia Ceramic

Surface : Pulishing

Dimension : according your request

technology : machining

standard : International Standard or as your request

MOQ : 5PCS

warranty : 2 years

Shipping : DHL EMS UPS FEDEX TNT

Item : Dust-proof Zirconia Ceramic Parts High Temperature Stirring Rod

OEM : yes and

Dust-proof Zirconia Ceramic Parts High Temperature Stirring Rod

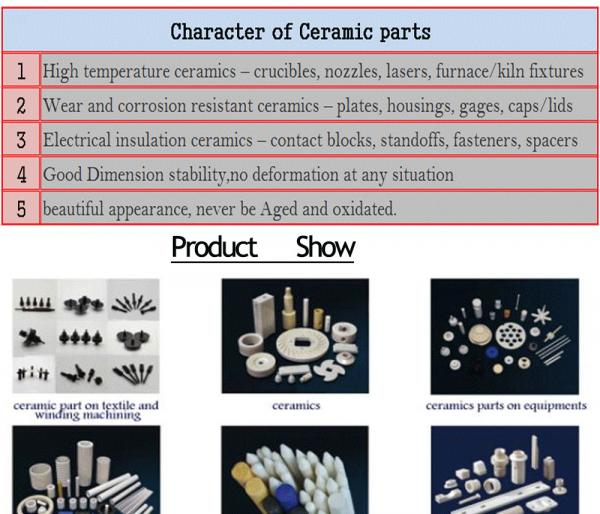

Main Properties of Zirconium Oxide Ceramics

| Item | Unit | Z95 |

| Type | - | Yttria Stabilized |

| Density | g/cm3 | 5.95 |

| Color | - | white |

| Water Absorption | % | 0 |

| Young Modulus | Gpa | 205 |

| Vickers Hardness | Gpa | 12 |

| Compressive Strength | Mpa | 2200 |

| Flexural Strength | Mpa | 900 |

| Thermal Conductivity | W/m.K | 2.20 |

| Thermal Shock Resistance | Δ(°C) | 280 - 350 |

| Max. Working Temp. | °C | 850 |

| Volume Resistivity | Ω ·cm | > 10^12 |

| Dielectric Constant | - | 26 |

| Dielectric Strength | kV/mm | - |

* Tests under room temperature environment;

* The above information is offered for comparison only. Exact

properties will vary depending on the manufacturing method

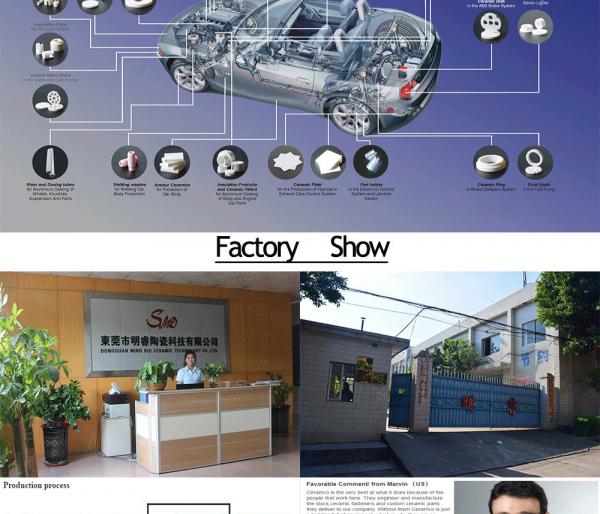

Alumina ceramic is kind of structural ceramics, with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, devices porcelain, spark plugs and other products. We can make the part by hot injection pressing, dry pressing, isostatic pressing and extrusion productive technology etc

We can customize according to customer's need

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Dust-proof Zirconia Ceramic Parts High Temperature Stirring Rod |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Dust-proof Zirconia Ceramic Parts High Temperature Stirring Rod |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .

|

|

Custom Machining Ceramic Threaded Rod Zirconia Ceramic Positioning Pins Images |